1. Assembly of frame

In ancient times doors from wood were manufactured manually. Nowadays many wood treatment processes are computer-assisted. However, production of Varadoor is different because we know when we should use equipment and when to entrust the work to hands of master workman.

After processing and in-size selection of all parts it is the time for assembly.

Parts of frame are jointed by workmen with secure fixtures. Door is assembled precisely by a template.

The process is optimized to the extent that assembly of one door framework takes 90 seconds at all.

Cellular filling materials – pasteboard filler parts – are inserted into frame to make the door light and save its initial proportions.

2. MDF parts

Some parts for future door are made from MDF. Door plat-bands (surface mounted parts that enframe door openings) and finishing accessories are also made from MDF. Thickness of MDF varies from 3 to 16 mm depending on type of part.

At the stage of splicing MDF parts with casing are glued to assembled frame from two sides which allows to obtain perfect flat surface of future door. For better fixing of casing the door is pressed down for 8 minutes.

3. Veneer

After gluing all parts are veneered (covered with natural wood veneer).

Varadoor doors are covered with natural wood veneer (thin leaf of natural wood) of any wood: ash-wood, oak-wood, venge, zebrano, etc.

We are serious about quality of both veneer and wood. After acceptance from suppliers veneer undergoes the following treatment: it is moistened and flattened for better splicing with workpieces. Veneer is selected according to tone to form symmetric pattern and texture. Splicing is performed on German equipment by Kuper.

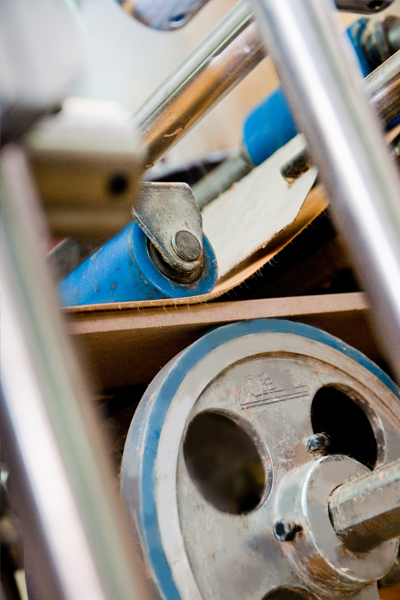

4. Calibration

The next stage involves cutting off of waste edges and calibration of door to fit to size. Calibration is followed by finishing: door leaf is grinded on gauge-grinding machine to remove all burrs.

5. Paint coating

At first, the finished door is coated with primer on varnish-and-paint line by Giardina. After that master workman matches the tones manually. Only manual coating and matching of tones provides perfect even colour of the door (since natural veneer of one species of wood can vary in tints).

After paint coating door is seasoned under natural conditions for 6-8 hours in separate room and under certain temperature.

Preformed glass can be inserted into door when paint coating becomes dry.

6. Acceptance

After painting each door is inspected by expert. Doors that have even insignificant defects are not allowed to glazing.

7. Glazing

Each Varadoor door model has glazy option. There is a separate glass manufacturing unit at the enterprise that produces various decorative components: glass fusing, stained glass, triplex glass, glass-painting, engraving, sandblasting.